A bridge between the past and tomorrow

Founded as a spin-off company of Joris Laarman Lab, an experimental playground set up to study and share the future, MX3D has been endlessly curious about the intersection of artistic form and functional objects. But the company was also deeply dissatisfied with the limitations of existing 3D printing technology.

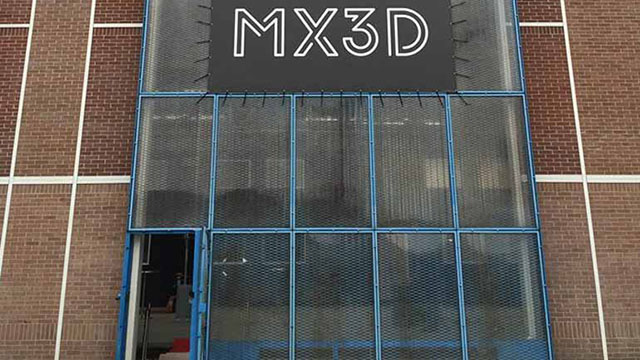

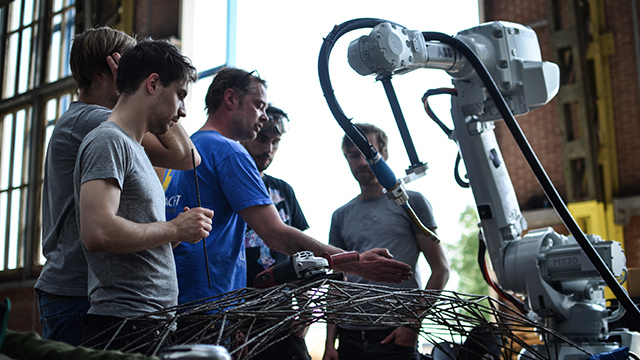

In 2014, MX3D invented an affordable multiple axis 3D printing tool – a combination of industrial robot and advanced welding machine controlled by complex software. Engineers and craftsmen now have the ability to print sustainable materials like metals and resin in virtually any shape and size.

The MX3D bridge is the ideal way to showcase this trailblazing technology. But it’s only the first step toward MX3D’s goal of creating robotic manufacturing solutions that do nothing less than transform industry and the arts.

Turning data into design

For creating large-scale objects literally out of thin air, the engineers at MX3D need to compute and manage enormous quantities of data. The ThinkStation P910 has the extreme performance edge to handle all of this data, running topology optimization applications like Autodesk Fusion 360 with ease.

To make changes on the fly, MX3D designers turn to the ThinkPad P40 Yoga, which ingeniously combines the sketching capabilities of a tablet and the power of a workstation.

"Everything is possible. If you put enough time and effort into it, you can do it."